Micromanufacturing: Revolutionizing Production for Small-Scale Industries

Micromanufacturing is reshaping the landscape of small-scale industries, offering unprecedented opportunities for precision, efficiency, and customization. This innovative approach to production is transforming how businesses create products, manage resources, and compete in increasingly specialized markets. As we delve into the world of micromanufacturing, we'll explore its potential to revolutionize traditional manufacturing paradigms and empower a new generation of entrepreneurs and craftspeople.

The Evolution of Micromanufacturing

Micromanufacturing has its roots in the miniaturization trends that began in the mid-20th century, particularly in the electronics industry. As demand grew for smaller, more sophisticated electronic components, manufacturers had to develop new techniques to produce these tiny parts with high precision. Over time, these methods expanded beyond electronics into other fields, driven by advancements in materials science, robotics, and computer-aided design.

The rapid progress in additive manufacturing technologies, particularly 3D printing, has been a significant catalyst for micromanufacturing’s growth. These technologies allow for the creation of complex geometries at microscopic scales, enabling the production of parts that were previously impossible or prohibitively expensive to manufacture using traditional methods.

Key Technologies Enabling Micromanufacturing

Micromanufacturing relies on a suite of advanced technologies to achieve its remarkable precision and versatility. Some of the key enabling technologies include:

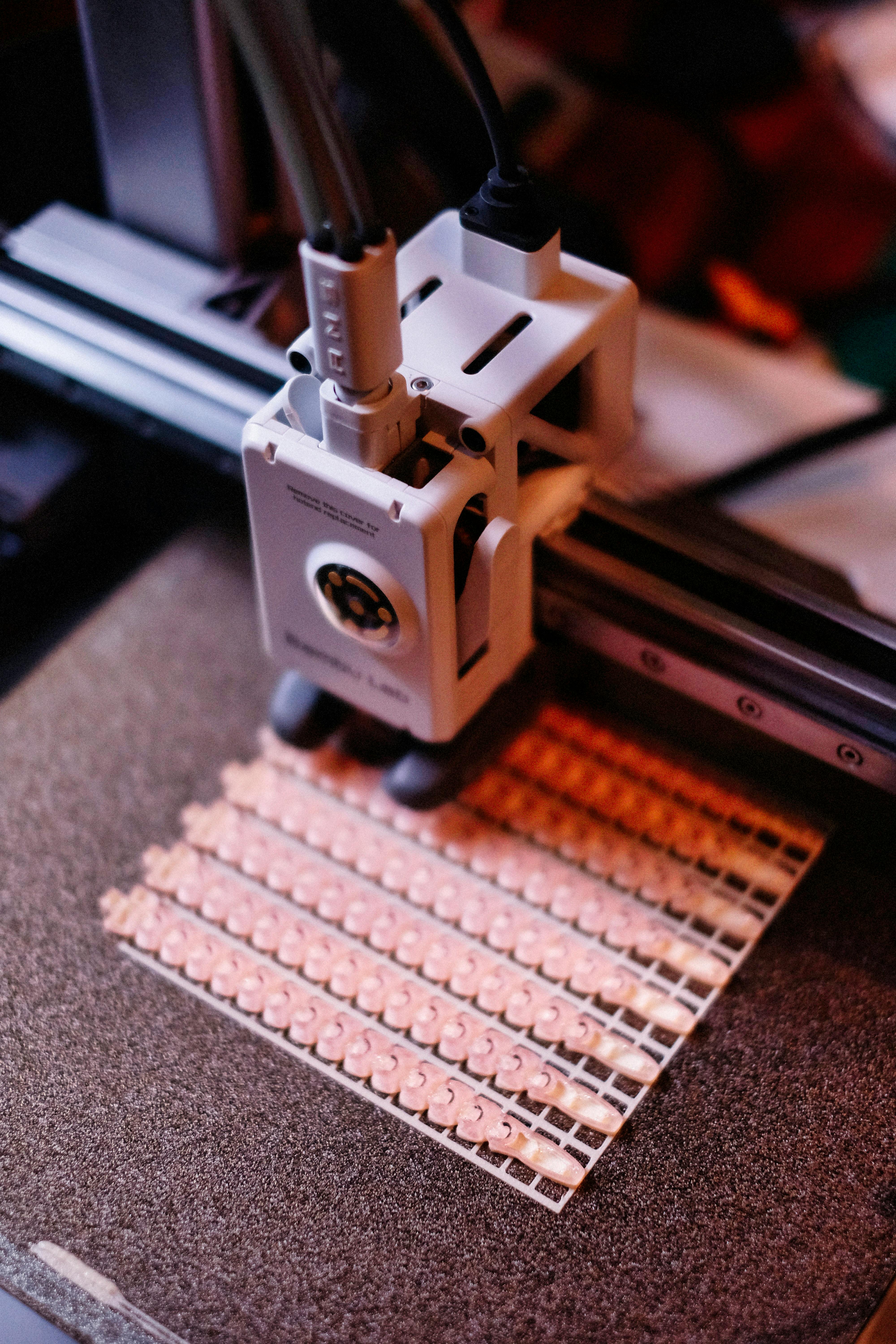

Laser Micromachining

Laser micromachining uses high-powered lasers to remove material with incredible precision, allowing for the creation of microscopic features on a variety of materials. This technique is particularly useful for creating small holes, channels, and surface textures in metals, ceramics, and polymers.

Microinjection Molding

This process adapts traditional injection molding techniques to produce tiny plastic parts with high accuracy. It’s widely used in the production of medical devices, micro-optics, and miniature electronic components.

Micro-EDM (Electrical Discharge Machining)

Micro-EDM uses electrical discharges to erode material from a workpiece, allowing for the creation of complex shapes in hard materials like steel and titanium. This technique is particularly valuable for producing micro-tools and precision components for industries like watchmaking and medical device manufacturing.

Applications and Industry Impact

The impact of micromanufacturing is being felt across a wide range of industries, each benefiting from the ability to produce smaller, more precise components:

Medical Devices

Micromanufacturing is revolutionizing the medical device industry by enabling the production of minimally invasive surgical tools, implantable devices, and diagnostic equipment. For example, microscale 3D printing is being used to create customized hearing aids and dental implants that fit patients with unprecedented accuracy.

Aerospace and Defense

In the aerospace sector, micromanufacturing techniques are being employed to create lightweight, high-strength components for aircraft and satellites. These techniques allow for the production of complex geometries that can significantly reduce weight while maintaining or even improving structural integrity.

Consumer Electronics

The ongoing trend towards smaller, more powerful electronic devices is heavily reliant on micromanufacturing. From the production of microprocessors to the creation of miniature sensors for wearable technology, these techniques are essential for pushing the boundaries of what’s possible in consumer electronics.

Challenges and Future Directions

While micromanufacturing offers immense potential, it also faces several challenges that must be addressed for wider adoption:

Quality Control and Inspection

As components become smaller, traditional quality control methods become increasingly difficult to apply. Developing new inspection techniques and standards for microscale production is crucial for ensuring consistency and reliability.

Material Limitations

Not all materials are suitable for micromanufacturing processes, and those that are may behave differently at microscopic scales. Ongoing research into new materials and their properties at the microscale is essential for expanding the capabilities of micromanufacturing.

Scaling Production

While micromanufacturing excels at producing small batches of highly specialized components, scaling up to mass production can be challenging. Developing strategies for efficient, high-volume micromanufacturing will be key to its broader adoption in industry.

Practical Insights for Embracing Micromanufacturing

• Start small: Begin by identifying specific components or products that could benefit from miniaturization or increased precision.

• Invest in education: Ensure your team is trained in the latest micromanufacturing techniques and technologies.

• Collaborate with experts: Partner with research institutions or specialized companies to access cutting-edge micromanufacturing capabilities.

• Consider hybrid approaches: Combine micromanufacturing techniques with traditional methods to optimize your production process.

• Focus on niche markets: Identify specialized markets where the unique capabilities of micromanufacturing can provide a competitive advantage.

Micromanufacturing represents a paradigm shift in how we approach production, particularly for small-scale and highly specialized industries. By enabling the creation of components and products at unprecedented scales of precision and complexity, it opens up new possibilities for innovation across a wide range of sectors. As technologies continue to advance and new applications emerge, micromanufacturing is poised to play an increasingly crucial role in shaping the future of industrial production. For businesses looking to stay at the forefront of their industries, embracing micromanufacturing could be the key to unlocking new levels of innovation, efficiency, and competitiveness.